Multi-Modal TMS Tracking: The 45-Day Configuration Playbook That Eliminates Visibility Gaps Between Ocean, Rail, and Road

Multi-modal shipments create tracking nightmares that single-mode TMS configurations simply can't handle. Container-to-truck handoffs fail 23% of the time because your ocean freight API speaks different languages than your trucking carrier API. Rail-to-road transitions? Even worse when port delays cascade through every downstream mode.

You need a TMS configuration that bridges these gaps without requiring your team to become integration specialists. This playbook walks through the exact 45-day process we've used across packaging manufacturers and heavy equipment shippers to eliminate visibility dead zones between transportation modes.

The Tracking Breakdown: Why Your Current TMS Can't Handle Modal Switches

Your TMS works fine when containers stay on ships or trucks stay on highways. The problems start at transition points where different transportation modes hand off shipments using incompatible data formats.

Ocean carriers provide container tracking through INTTRA or similar platforms with 4-6 hour update delays. Rail operators like BNSF push status updates via EDI with different timing intervals. Local trucking fleets use GPS pings every 15 minutes. When a container moves from port to rail yard to final delivery truck, each handoff creates potential visibility gaps.

MercuryGate handles these transitions through universal shipment identifiers, while Descartes relies on carrier-specific APIs. Cargoson takes a hybrid approach with standardized data mapping across modes. The technical approach matters less than consistent execution.

The real problem isn't technology. Most TMS teams configure tracking for their primary transportation mode, then treat other modes as afterthoughts. You get excellent truck visibility but lose containers in rail yards for days.

Pre-Configuration Audit: Map Every Modal Touchpoint

Before changing configurations, document how shipments actually move through your network. Not how they're supposed to move. How they move when ports get congested and rail schedules slip.

Start with your top 20 shipping lanes by volume. For each lane, identify every mode transition: port discharge to rail pickup, rail delivery to trucking depot, cross-dock to final mile carrier. Note the average dwell time at each transition point and which party controls status updates.

Your ocean freight forwarder might provide excellent port-to-port tracking but go silent during customs clearance. Rail operators excel at terminal-to-terminal updates but struggle with first-mile and last-mile handoffs. Document these gaps specifically.

Check API capabilities by transportation mode. Ocean carriers typically offer standardized container tracking APIs with 2-4 hour update frequencies. Rail operators provide EDI-based updates with variable timing. Trucking carriers range from real-time GPS to manual check-calls.

The audit should reveal patterns. Asian import containers might have excellent ocean visibility but disappear for 24-48 hours during port discharge. Domestic intermodal shipments might track perfectly on rail but lose visibility during truck pickup scheduling.

Universal Tracking References: The Foundation That Makes Everything Work

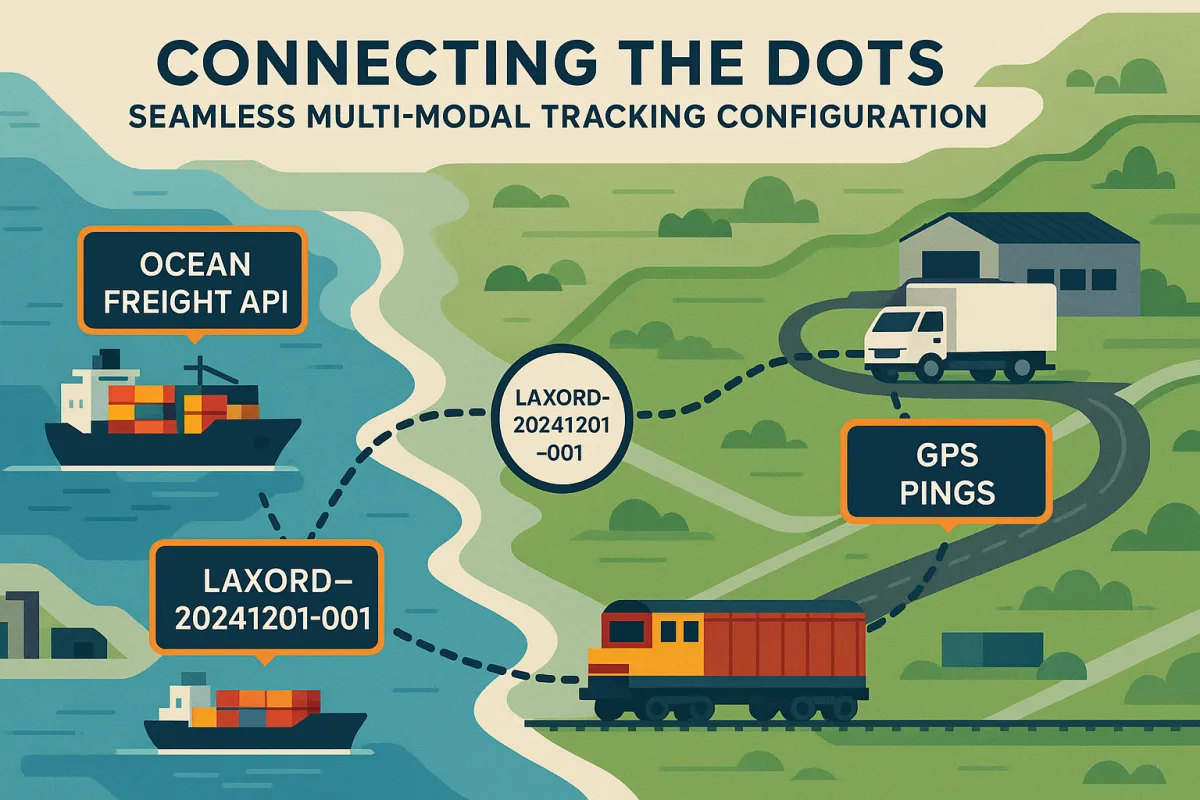

Multi-modal tracking fails when each transportation mode uses different shipment identifiers. Container numbers work for ocean freight but mean nothing to trucking dispatchers. Bill of lading numbers track truck movements but don't connect to rail car assignments.

Create a master shipment identifier system that works across all modes. This isn't your order number or invoice reference. This is a tracking number specifically designed to follow physical shipments through mode transitions.

The master identifier should include the origin-destination pair, departure date, and a sequential number. Format: LAXORD-20241201-001 for the first shipment from Los Angeles to Chicago on December 1st. Simple enough for dock workers to reference, unique enough for API queries.

Configure your TMS to generate these master identifiers at shipment creation, not at first mode booking. Ocean bookings, rail reservations, and truck dispatches should all reference the same master identifier. When modes change, the tracking reference stays constant.

Map existing identifiers to your master system. Container MSCU1234567 becomes child reference under LAXORD-20241201-001. Rail car BNSF567890 gets mapped to the same master identifier. Truck dispatch number 45678 connects to the same shipment family.

Database schema changes support this hierarchy. Create a parent shipment table with master identifiers, then child tables for mode-specific references. API integrations should always lead with the master identifier, then include mode-specific references as metadata.

Mode Transition Protocols: 15-Minute Handoff Configuration

Shipments lose visibility during handoffs because nobody owns the transition period. Ocean carriers consider delivery complete when containers reach port discharge. Rail operators don't start tracking until containers reach their rail yards. The gap between discharge and rail pickup becomes a visibility black hole.

Configure automatic transition notifications that trigger 15 minutes before expected handoffs. When ocean carriers report "container available for pickup," your TMS should immediately notify rail operators and expect pickup confirmation within your defined window.

Set up three-party notification chains for each transition. Ocean-to-rail transitions need notifications to the rail operator, drayage carrier, and your internal operations team. Rail-to-truck transitions require notifications to the delivering rail terminal, pickup trucking company, and destination facility.

Transporeon excels at these multi-party notifications through their carrier network integrations. nShift provides solid API connections for European rail transitions. Cargoson offers flexible notification workflows that adapt to different regional requirements.

Configure timeout protocols for missed handoffs. If expected rail pickup doesn't occur within 4 hours of container availability, escalate to operations. If truck pickup doesn't happen within 2 hours of rail delivery, trigger alternative carrier outreach.

The notification content matters. Don't send generic "shipment update" messages. Send specific transition details: "Container MSCU1234567 available for rail pickup at Long Beach Terminal Island, Bay 23, expected pickup window 14:00-16:00 PST."

Exception Protocols: 3-Tier Response for Modal Delays

Port congestion doesn't just delay ocean shipments. It cascades through every downstream transportation mode. When containers sit 3 extra days at Long Beach, rail schedules slip, truck pickups get rescheduled, and final delivery dates become fiction.

Configure exception handling that accounts for modal interdependencies. Tier 1 exceptions affect single modes without downstream impact. Tier 2 exceptions impact subsequent modes but stay within recovery windows. Tier 3 exceptions cascade across multiple modes and require customer notification.

Port delays over 24 hours automatically become Tier 2 exceptions. Your TMS should immediately check rail schedule flexibility and truck carrier capacity for affected lanes. If rail schedules can absorb 1-2 day delays without impacting final delivery, maintain original customer commitments. If not, escalate to Tier 3.

Rail delays over 12 hours trigger automatic truck carrier outreach for expedited final delivery. If expedited trucking can recover lost time within reasonable cost parameters, execute the change automatically. If cost impact exceeds your predefined thresholds, escalate for manual approval.

Customer notification triggers vary by exception tier and customer priority. Tier 1 exceptions might only update internal tracking without external communications. Tier 2 exceptions could trigger automated delay notifications to standard customers but require manual outreach to key accounts. Tier 3 exceptions always require immediate customer contact with alternative delivery options.

Multi-Modal Dashboard Configuration: KPIs That Actually Drive Action

Standard TMS dashboards show transportation performance by individual mode. Ocean freight on-time performance, rail transit consistency, trucking delivery reliability. These metrics miss the point. Multi-modal performance depends on seamless transitions, not individual mode excellence.

Configure dashboards around journey completion metrics. Track end-to-end on-time performance from origin pickup to final delivery, regardless of how many modes handle the shipment. Break down delays by transition point, not transportation mode.

Mode transition accuracy becomes your primary KPI. Measure the percentage of handoffs that occur within planned windows. Target 95% for controlled transitions like scheduled rail pickups, 85% for variable transitions like port discharge timing.

Handoff timing analysis reveals systemic problems. If port-to-rail transitions consistently take 6 hours longer than planned, investigate drayage carrier performance or terminal processing delays. If rail-to-truck handoffs show wide variability, examine truck carrier scheduling practices.

SQL queries for transition analysis should join shipment events across mode changes:

SELECT master_shipment_id, origin_mode, destination_mode, planned_transition_time, actual_transition_time, DATEDIFF(minute, planned_transition_time, actual_transition_time) as delay_minutes FROM shipment_transitions WHERE transition_date >= '2024-01-01' ORDER BY delay_minutes DESC;

Visual timeline configurations work better than traditional charts for multi-modal tracking. Show planned versus actual progression through each transportation mode with clear indicators for transition delays or acceleration.

45-Day Implementation: Week-by-Week Rollout Strategy

Don't attempt full multi-modal visibility configuration overnight. Rollout complexity increases exponentially when you try to change everything simultaneously. Phased implementation lets you test configurations before they impact live shipments.

Weeks 1-2: Data Architecture and Audit Complete your modal touchpoint analysis and implement master shipment identifier systems. Configure database schemas without connecting external APIs. Test identifier generation and mapping logic using historical shipment data.

Weeks 3-4: Primary Carrier Integrations Connect APIs for your highest-volume transportation modes first. If 60% of shipments use ocean freight, start with ocean carrier integrations. Test data flow and notification systems using controlled shipment samples.

Weeks 5-6: Transition Protocol Testing Activate handoff notifications and exception handling for integrated modes only. Monitor transition accuracy and response times. Adjust timeout windows and escalation triggers based on actual performance data.

Weeks 7-8: Secondary Mode Integration Add remaining transportation modes and test full multi-modal workflows. Start with low-volume lanes that can tolerate configuration adjustments. Validate end-to-end tracking accuracy before expanding to critical shipments.

User training should follow transportation mode expertise. Ocean freight specialists need different dashboard configurations than trucking coordinators. Rail operations teams require specific exception handling knowledge that doesn't apply to final mile delivery management.

Gradual feature activation prevents overwhelming existing operations. Start with enhanced visibility dashboards, then add automatic notifications, finally enable exception handling protocols. Each activation phase should demonstrate clear value before adding complexity.

Track implementation success through specific metrics: transition timing accuracy, exception response times, customer notification speed, and overall journey completion rates. Target 15% improvement in multi-modal on-time performance within 90 days of full rollout.

The payoff justifies the complexity. Manufacturers typically see 25% fewer customer service calls about shipment status and 18% improvement in inventory planning accuracy. Retailers report better stock availability during peak seasons when multi-modal shipments perform predictably.

Start your configuration audit next Monday. Pick your three highest-volume multi-modal lanes and map every transition point. You'll find gaps that explain those missing container updates and delayed delivery notifications. Fix the visibility gaps first, then automate the responses.